Balancing the mobile inverted pendulum.

"A practical approach"

Mechatronics lecture by Keith Colson

Why build a mobile

inverted pendulum?

- The mobile pendulum is obviously a good practical

challenge in dynamic control theory

- The project covers mechatronics very well as it includes

electronics, mechanics, software and little luck..

Where do you start?

- Big motor = big motor controller, heavier batteries and

vice versa.

What motors should

I use?

- On a servoing (q) system a low backlash (q) motor is

going to make life easier and smoother on this task (q).

- Gearing: Scratch or integrated. Time and cost.

- Motor size (what's easy to get your hands on) or pendulum

size?

- Faulhaber

motor: They dont get much nicer than Swiss designed

core-less motors. High efficiency, geared, zero-backlash,

expensive.

What about the

wheels?

- Wheel circumference * n revs per second = meters per

second.

- Home brew encoder. (unfinished)

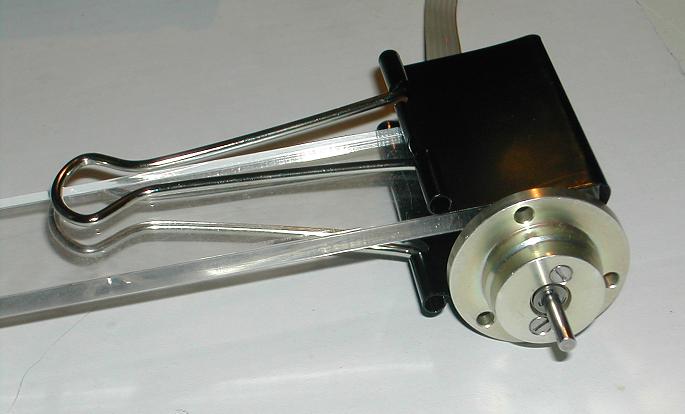

The Chassis

Height = pendulum frequency.

(about 1 second or 1 Hz in my case) / 2 due to CG.

Height = pendulum frequency.

(about 1 second or 1 Hz in my case) / 2 due to CG.

- Short = faster response needed.

- Battery weight and location. Battery count.

- Practical pendulum height = wheel diameter * 3,

ascetically pleasing too, proportionate.

- Acrylic looks nice, fairly light, machines easily.

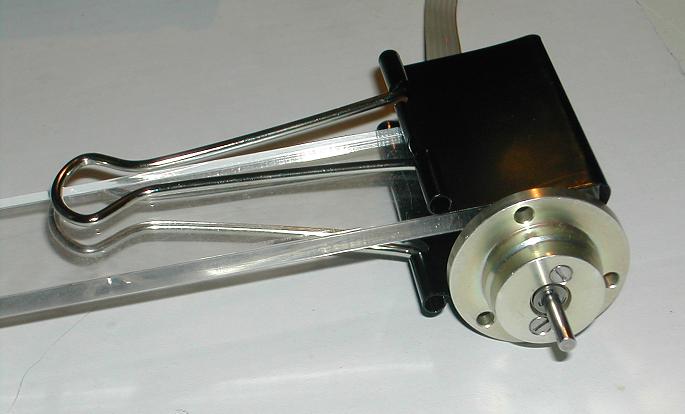

- Finished mechanics using only 3 screws. Learn to bypass

screws.

- Motor mounting with bulldog clip, fast easy, flexible.

lets not waste time machining stuff we don't need to..

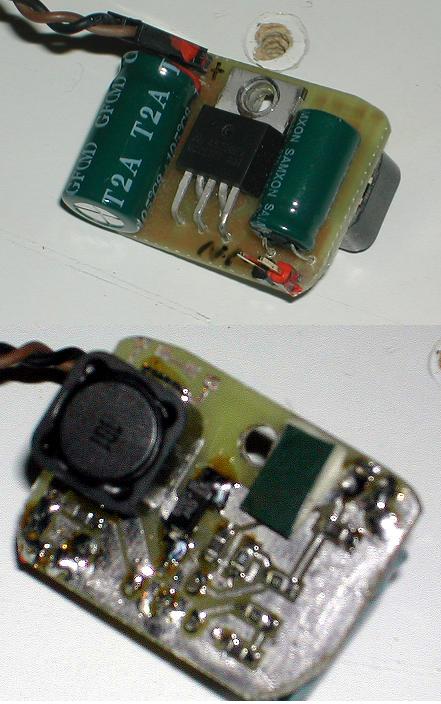

The Motor driver

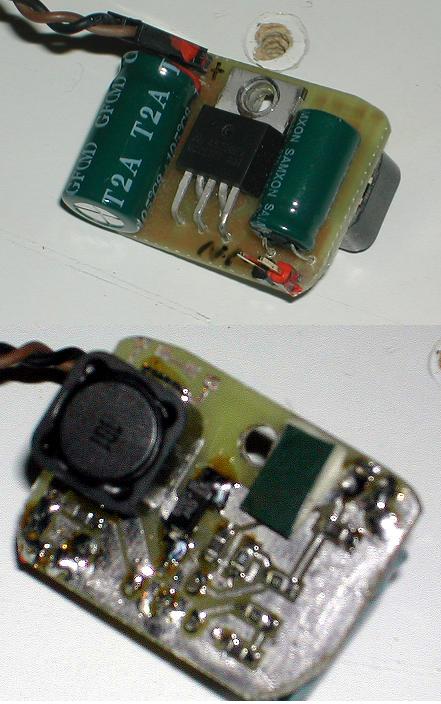

- H-bridge motor controller, small, simple.

- Board can fit on back of small motors

The Power supply

- 4 x 1.5V AA batteries = 5.2 to 6 volts working range.

- 12 volts out from 5 to 6 volts in using boost regulator.

- UC2577 boost regulator simple solution.

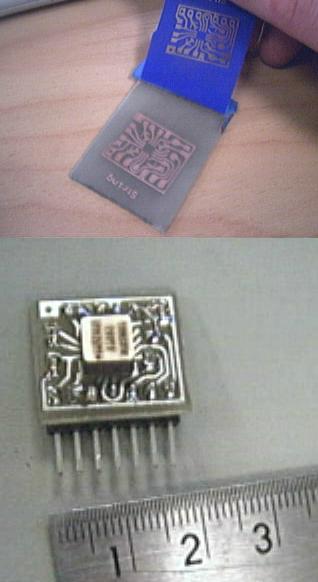

- Press'n peel board (one afternoon)

- Mark both male and female connectors with nail polish so

polarity is maintained.

- Nail polish stops smoke leaks.

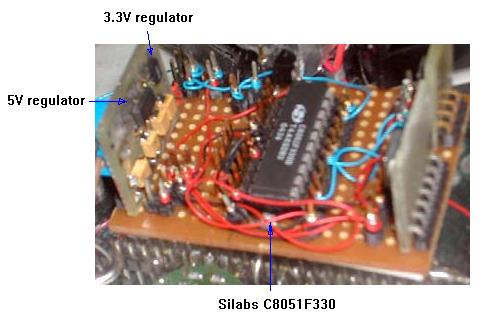

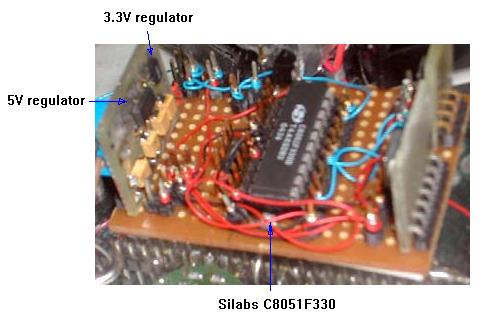

The Microprocessors

2 x Silabs 8051 variant 25 mips,

C8051F330

2 x Silabs 8051 variant 25 mips,

C8051F330

- Serial for coms between micros

- Keil compiler (fast floating point)

- 5 volt and 3.3 volt power-supply

- Wire wrap is fast, easy to change configuration.

- SIP and vero (strip) board = fast assembly

Simple Balance

- Tune motor PID control loop.

- Integral limit added to aviod integrator wind up.

(saturation)

- Add IMU when confident with performance.

The Inertial

Measurment Unit (IMU).

Analog devices

Gyroscope - ADXRS300 32 pin BGA

Analog devices

Gyroscope - ADXRS300 32 pin BGA

- Analog devices 2 axis accelerometer - ADXL202

- 2 boards SIP design. Press'N'Peel board.

- BGA soldered in $50 toaster oven.

- Gyroscope = high frequency rate of rotation (relative)

- Accelerometer = low frequency gravity vector (absolute)

The Kalman Filter.

- Kalman filter removes gyro DC bias and drift..

- Kalman filter low pass filters accelerometer.

- Kalman filter fuses high frequency and low frequncy

signals to give absolute gravity vector.

Version 2 of the

Inertial Measurement unit.

- For future projects, I2C, serial support

- Very small 50x20x9mm, Kalman filter built in.

Final touches

Added a hat to stop it smashing

into the floor when it falls over. (Kids toy ball)

Added a hat to stop it smashing

into the floor when it falls over. (Kids toy ball)

- Turn off the motors when fallen.

- Video of the pendulum balancing. Yes, it is programmed to

turn in circles.

Conclusion

- The inverted pendulum in its simplest form proves to be a

challenge. While it did balance many improvements could

be made.

- A radio control for testing purposes

- A way to get back up after falling over.

- Motor/wheel encoders for more stable control.

- "Smart" closed loop motors each with their own

processor and PID control loop.

- Smart motors can then be used in other projects.

- Motors and IMU set up as I2C slave devices with one

master microprocessor.

- I2C has only 4 wires. 5V, 0V, Clock, Data. Tidy design

with a daisy chain cable.

- Autonomous operation via sensors.

Questions ?

Height = pendulum frequency.

(about 1 second or 1 Hz in my case) / 2 due to CG.

Height = pendulum frequency.

(about 1 second or 1 Hz in my case) / 2 due to CG.

2 x Silabs 8051 variant 25 mips,

C8051F330

2 x Silabs 8051 variant 25 mips,

C8051F330 Added a hat to stop it smashing

into the floor when it falls over. (Kids toy ball)

Added a hat to stop it smashing

into the floor when it falls over. (Kids toy ball)